-

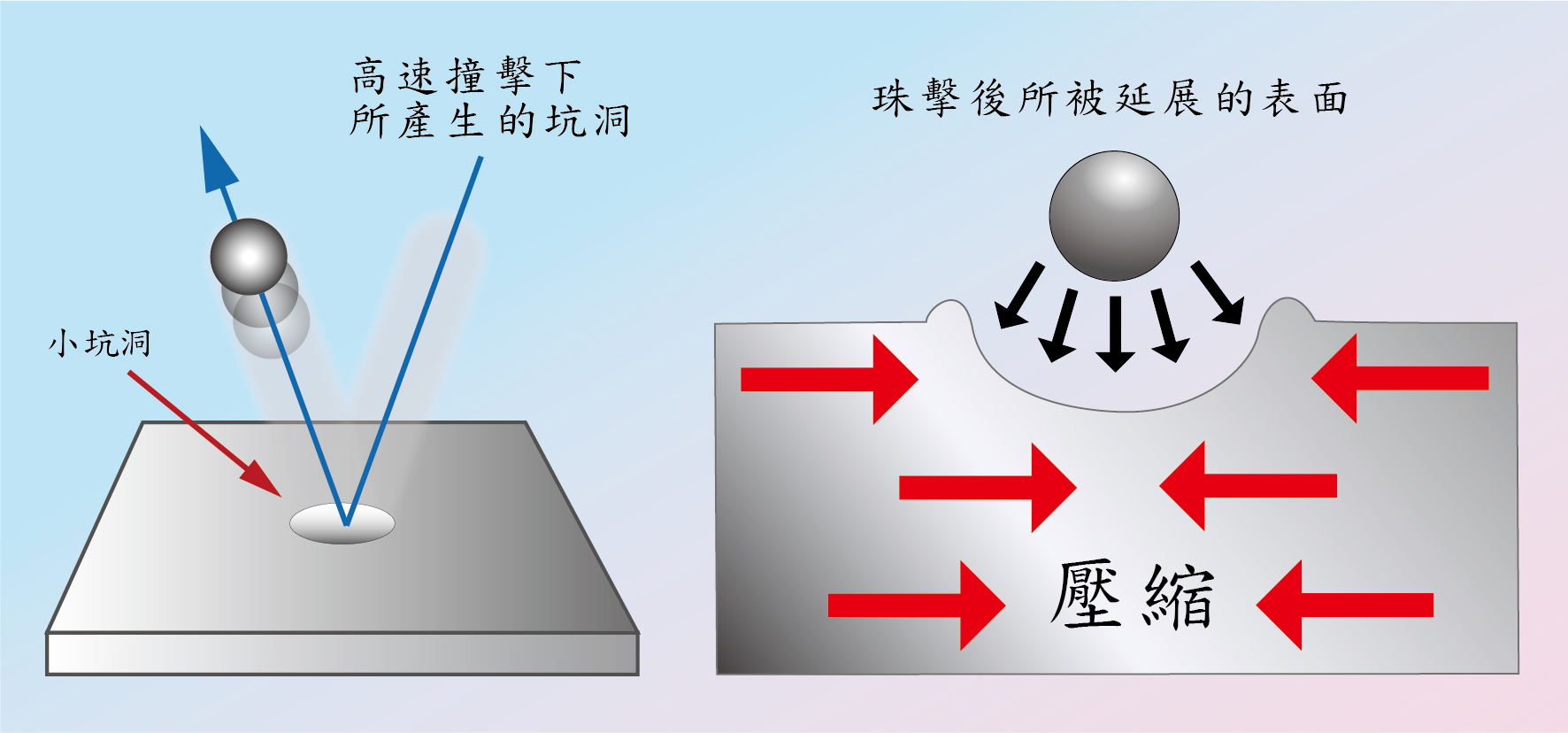

Shot peening is a cold working process, which involves bombarding the metal surface with countless fine particles at high speed to create tiny indentations or holes. After the metal surface is shot peening, work hardening, grain refinement, and residual compressive stress will occur ... The principle is similar to how the ancients used constant beating when forging knives to increase the hardness and strength of the blade. The strong residual compressive stress generated by bead blasting will inhibit the growth of micro-cracks on the metal surface, reduce crack tip corrosion and increase workmanship. The fatigue life of parts is an indispensable process technology for modern high-end metal manufacturing industries (such as aerospace, automobiles and motorcycles, and precision machinery).

-

The process parameters of bead blasting strengthening include: bead blasting method, bead blasting time, dent depth, bead blasting speed (air pressure flow), bead blasting amount, bead blasting angle, construction temperature, stress distribution, etc.

-

The most important parameters in the bead beating process are the material, specific gravity, hardness and particle size of the bead beating powder used .

-

In the bead-beating modification and strengthening process, the hardness of the particles used needs to be higher than that of the workpiece. The higher the hardness of the particles, the better the strengthening effect. In addition, the specific gravity of particles is also directly proportional to the strengthening effect.

-

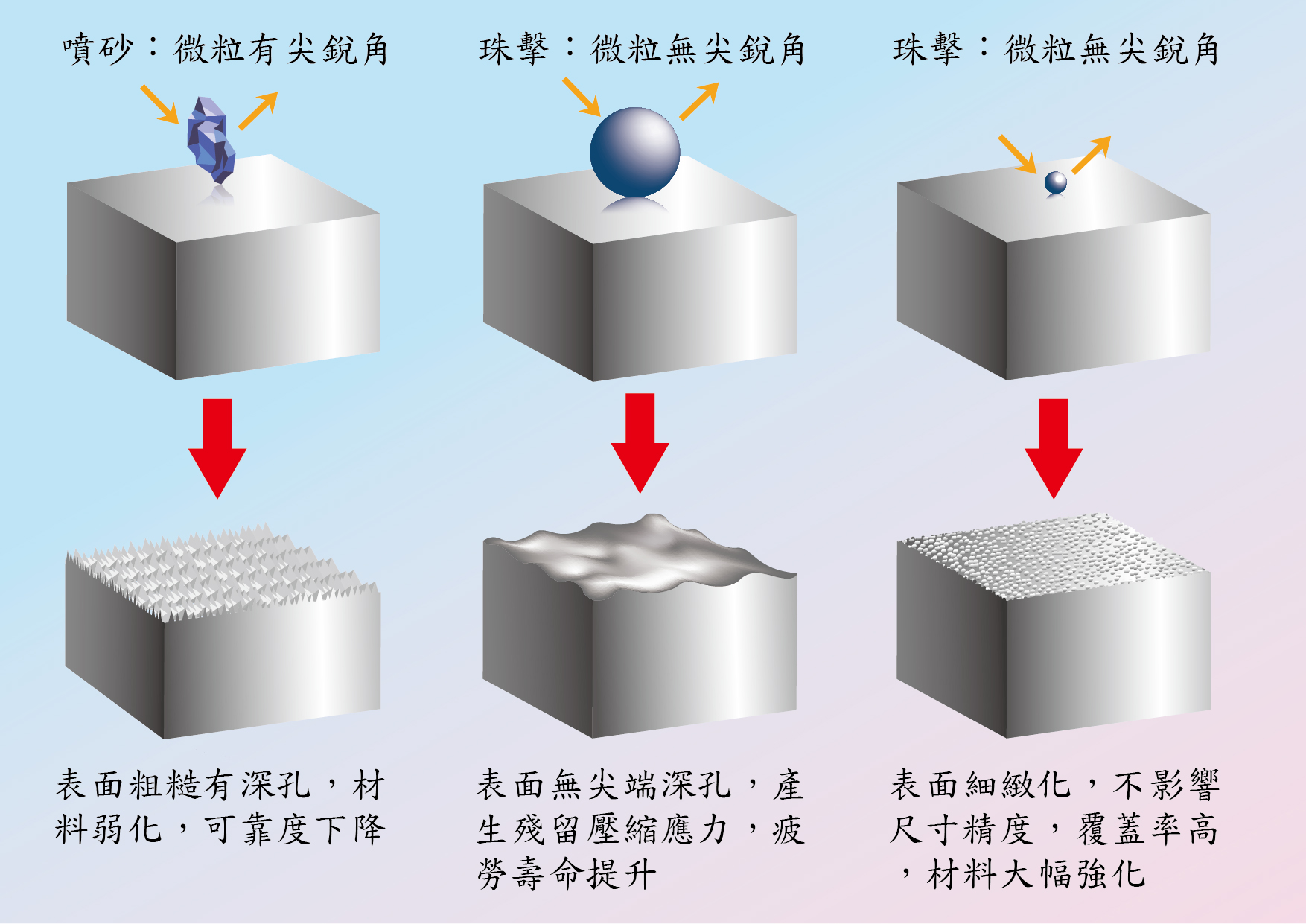

In the bead-beating process, the closer the particle shape is to a true circle , the better the bead-beating strengthening effect will be. The shape of the bead-blasted powder material must not have sharp angles, otherwise it will cause micro-cracks on the surface of the workpiece and reduce the fatigue life of the material. Therefore, the cracked bead-blasted powder needs to be filtered and removed to avoid negative effects.

|

|